As I mentioned in previous posts, we had problems with our

leaf spring hangers last Spring. Since

that time, Dad has been inspecting the issue regularly. When he recently got

under the trailer and removed some of the components of the suspension, he uncovered

even further problems associated with the OEM (or as Dad explained the

“original equipment manufacturers”) design.

Since Dad is better suited to explain what he found and document the repair process to our home on wheels, I am turning over the rest of this

post to him. (He’s got my head spinning

already! Time for cheese--my perfect cure for a headache!)

Thanks Popo. Well here is my one and maybe only shot at

posting on his blog. (not maybe, Dad. This is definitely your only shot! I've had to spent too much time editing!)

The first order of business was to make the areas of the

suspension accessible, so I removed the tires on each side by un-torquing the

lug nuts. Once the tires were removed, I

raised the trailer further by using the auto-leveling hydraulic jacks that

support the trailer when we are stationary. Then I removed the weight from the

spring hanger bolts in order to remove them. This was done by jacking each

spring just enough to allow the bolt to slide out of the spring. I also placed

blocking under the wheel drum so that in case the jack slipped, the axle would

not move.

Once the bolt at each hanger was loosened and removed, I inspected

the hanger assembly. As you will notice in the photo below, there was

significant damage to the OEM 3/16” steel. The actual slot that the bolt rides

in was elongated and the edges were being peened over. This reflects the

tremendous abuse these hangers absorb during the course of traveling down the

road. Couple that with the 12,000 miles for our trip to Alaska, they really

took a pounding.

To repair this systemic problem I decided to purchase

Lippert’s aftermarket Correct Track II hanger extensions. As you see in later

pictures, these extensions were obviously created to address the very issue we

experienced.

In order to properly install the new hanger brackets, I

modified the OEM hangers by using a grinder with cut wheels to remove the

flanges on either side that hold the OEM octagon cam. When using a grinder or any power equipment I

always use proper PPE (personal protective equipment) such as safety glasses,

gloves, and in this case, a long sleeve shirt.

Popo took photos of me cutting the flanges off, grinding them

smooth and removing the peened or coined edges of the slots.

I cleaned the steel hangers with mineral spirits and

alcohol, then repainted the exposed steel with a good heavy duty paint.

I installed the new aftermarket hanger assembly from Lippert

on top of the old hangers. Observe in the close up picture of the hanger: Lippert added a ¼” steel plate to the side.

This plate, along with the increased thickness of the hanger, now provides a ½”

surface for the new bolts to ride on. Just a little bit more beefy, huh?

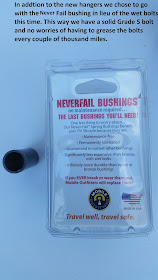

In addition to new hangers, I purchased Lippert Never Fail

bushings in lieu of the standard brass bushings. In subsequent pictures you

will see why. I also opted to use plain

Grade 5 bolts instead of the OEM greased wet bolts because I strongly believe the

hollow bolt riding on the steel hanger will wear out over time (like it did

previously), cut through, and fail. And

hopefully, the Never Fail bushings require less maintenance.

I aligned the new hangers on either side of the existing hangers

and temporarily thru-bolted them together so I could drill a new upper hole for

the additional 1/2” bolt. Extreme care

must be taken to ensure the holes align on either side.

Once the holes were drilled, the hangers were removed. I then

placed a spacer tube between the existing hanger extensions in order to keep

the hanger from collapsing when I tightened the new bolts up.

After installing the new hanger extensions, I replaced the

brass bushing on the leaf spring with the Never Fail bushings.

The last step for each hanger was to install the adjustable

octagonal cam. This cam is the basis for the entire Correct Track II design

from Lippert. The cam allows for adjustment of the axle by rotating it up to 1”

front to back. By design, this aligns the axles with the trailer to ensure

proper travel of the wheels to each other. Since I did not notice any unusual wear

on the tires nor misalignment while traveling down the highway, I chose to set

each cam in the same position at each front and rear location.

Each hanger set up took approximately 2 hours to complete,

total of 8 hours for the entire repair procedure.

Once each side was completed, I re-torqued the tires to 130

Ft/Lbs and lowered the trailer jacks so the weight was placed on the tires

before re-leveling the coach.

So as you will see from the next pictures, these are the

failed or failing components that I removed. Note that the brass bushings, even

with the proper greasing of the wet bolts, still failed (which I took into

consideration when determining to use Grade 5 bolts and Never Fail bushings).

Careful examination of the wet bolts indicated wearing where

they ride on the steel hangers which led to one bolt failing last year and

eventually another failure down the road.

Considering that we subject our home on wheels to a 9.0

earthquake each time we take it on the road, these are things that will always

take a beating and must be on our inspection list on a more frequent basis.

Wow, writing a blog post is a lot of work. (Really?) I

think I will stick to working on the mechanical things on our home and leave

the writing to PoPo! (An excellent

idea, Dad!)

Oh WOW PoPo - be glad Dad had the tools, skills and time to do this! A major project!!! I'm sure most who go to Alaska have a damage report afterwards, glad ours was minimal :)

ReplyDeleteNicely done! They look like they took a beating but should be good to go now!

ReplyDelete